PCD Ball End Mill with Corner Radius

PCD Ball End Mill with Corner Radius can achieve the effect of mirror processing, with high processing efficiency and long service life.

Item Name: PCD Ball End Mill with Corner Radius

Material: PCD and Tungsten Carbide

Application: Suitable for semi-finishing and finishing surfaces of graphite, ceramics, sapphire and glass.

Introduction

Crownkyn Superhard PCD Ball End Mill with Corner Radius is designed for semi-finishing and finishing surfaces of graphite, ceramics, sapphire and glass. Adopting to the latest patent groove design and the minimum width of 0.01mm, to ensure excellent rigidity and sharpness, the best material removal rate. The tool profile precision is controlled within 3μm to improve the surface finish of the workpiece.

Features

- Patented flute design

- Optimal material removal rate

- Excellent chip evacuation

- Enhanced workpiece cosmetics

- Minimum Flute with 0.01mm

- Tool contour accuracy controlled within 3μm

- Flutes stay in shape for a long time

- Tool life +400% vs. imported PCD-coated tools

Specification

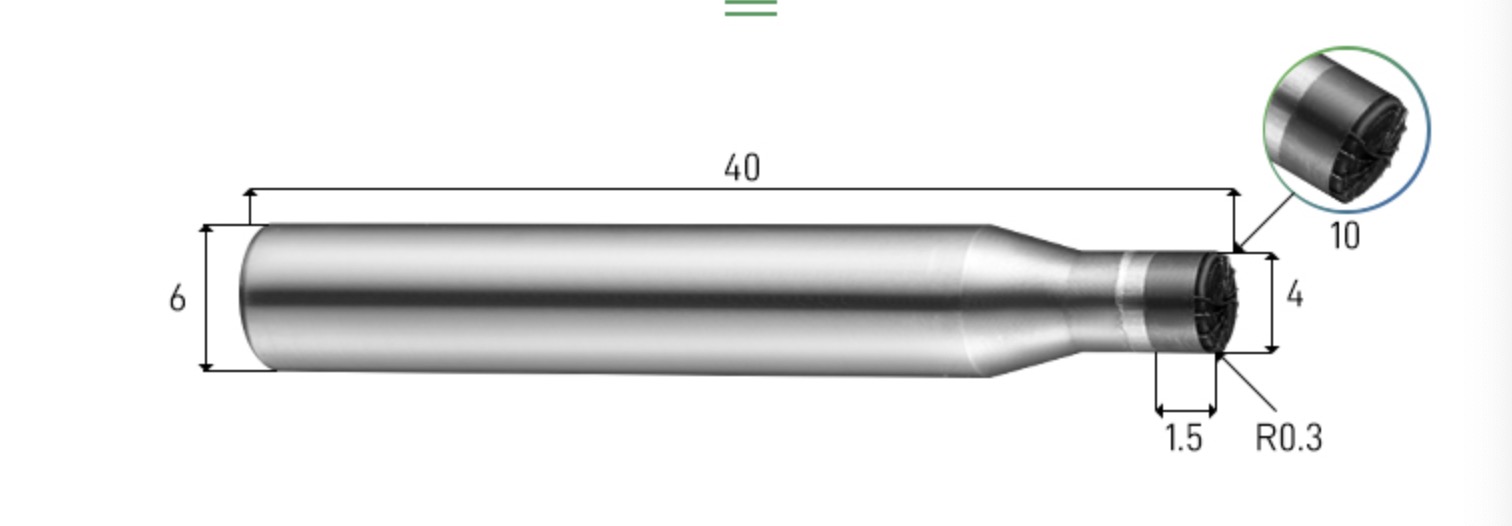

| Specification | Overall length(mm) | Cutting Edge Length(mm) | Diameter(mm) | Corner Radius(mm) | Shank Diameter(mm) | No. of Flute |

| D2xR4xR0.3×1.2x40LxD4-16F | 40 | 1.2 | 2 | 4/0.3 | 4 | 16 |

| D4xR10xR0.3×1.5x40LxD6-10F | 40 | 1.5 | 4 | 10/0.3 | 6 | 10 |

| D6xR20xR0.5×2.5x45lLxD6-15F | 45 | 2.5 | 6 | 20/0.5 | 6 | 15 |

Applications

PCD Ball End Mill with Corner Radius and Multi Flutes is processed and shaped by highly complex laser technology to achieve precise and fine cutting edges without burn burrs,which is suitable for processing graphite, ceramic.