Abstract: Grinding paste is a kind of surface precision machining. The surface roughness of the workpiece can be improved by using the grinding effect of abrasive paste. The diamond grinding paste is used to grind hard and brittle materials for a high surface finish. How to use diamond grinding compound? The following is the introduction and usage of diamond grinding paste.

Introduction to diamond grinding paste

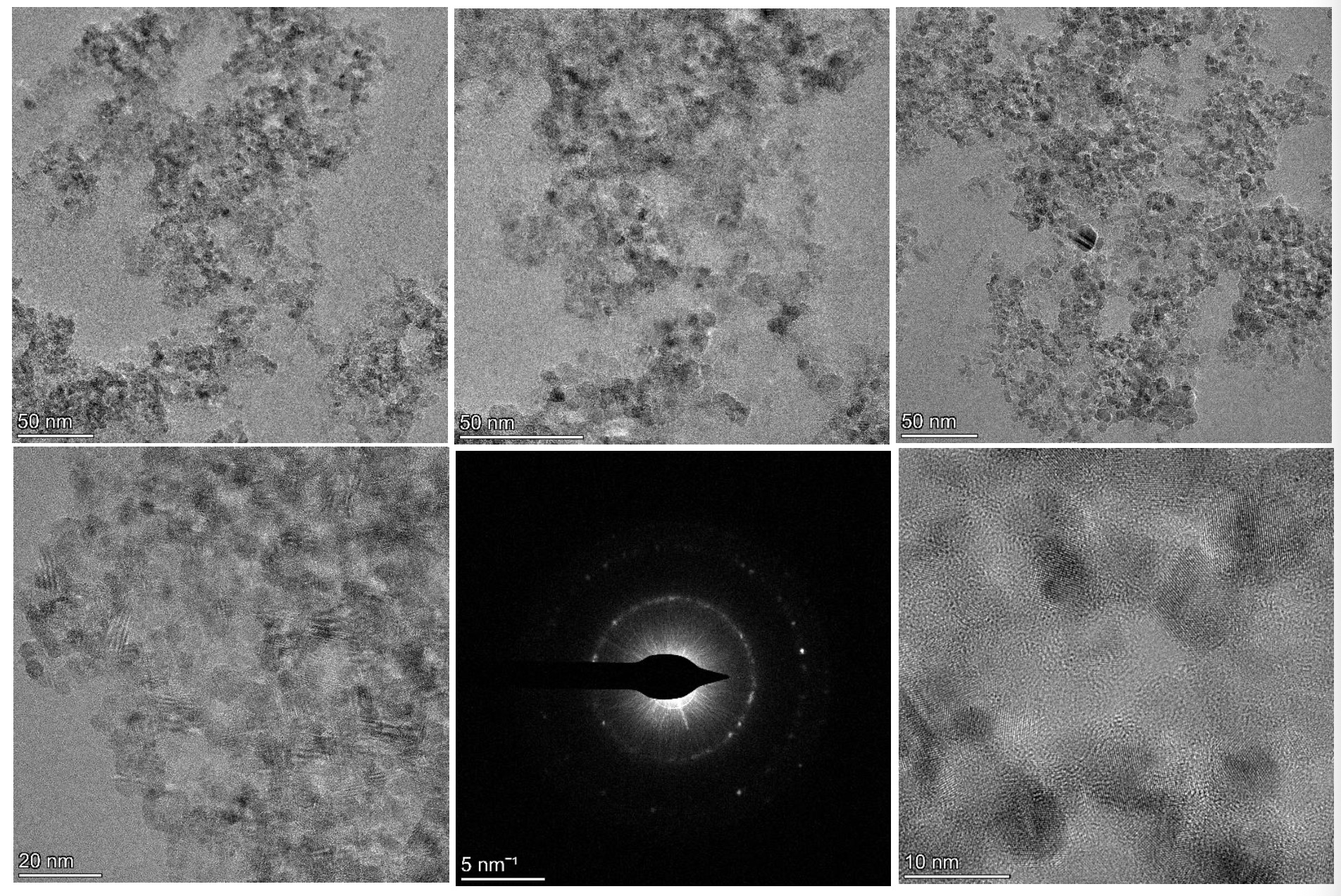

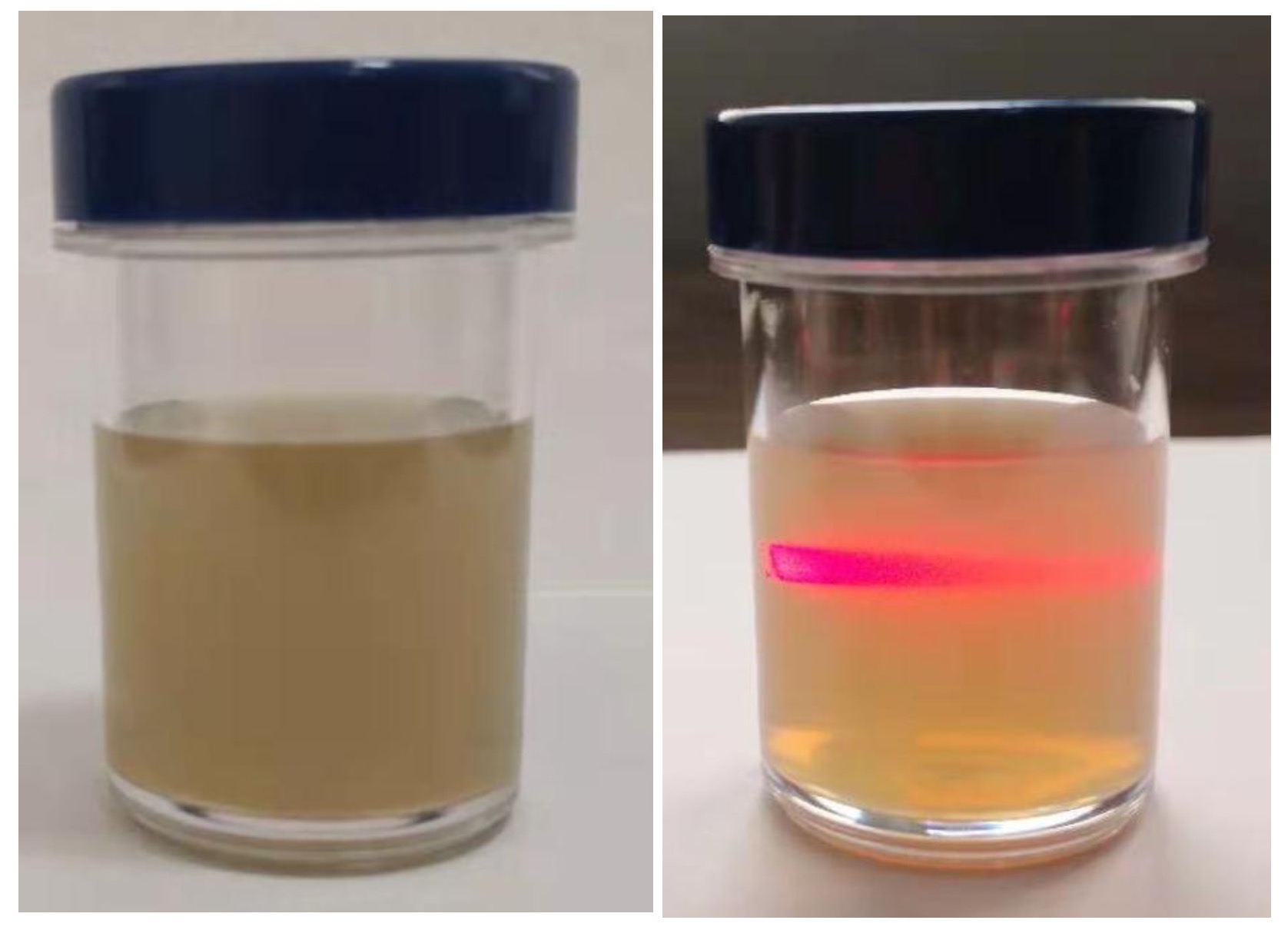

The diamond abrasive paste is finely formulated with fine diamond powder and other raw materials. It is an ideal abrasive paste for grinding and polishing. It has good lubrication and cooling properties. The diamond particles in the diamond compound have high hardness, uniform particle size, and a good grinding effect.

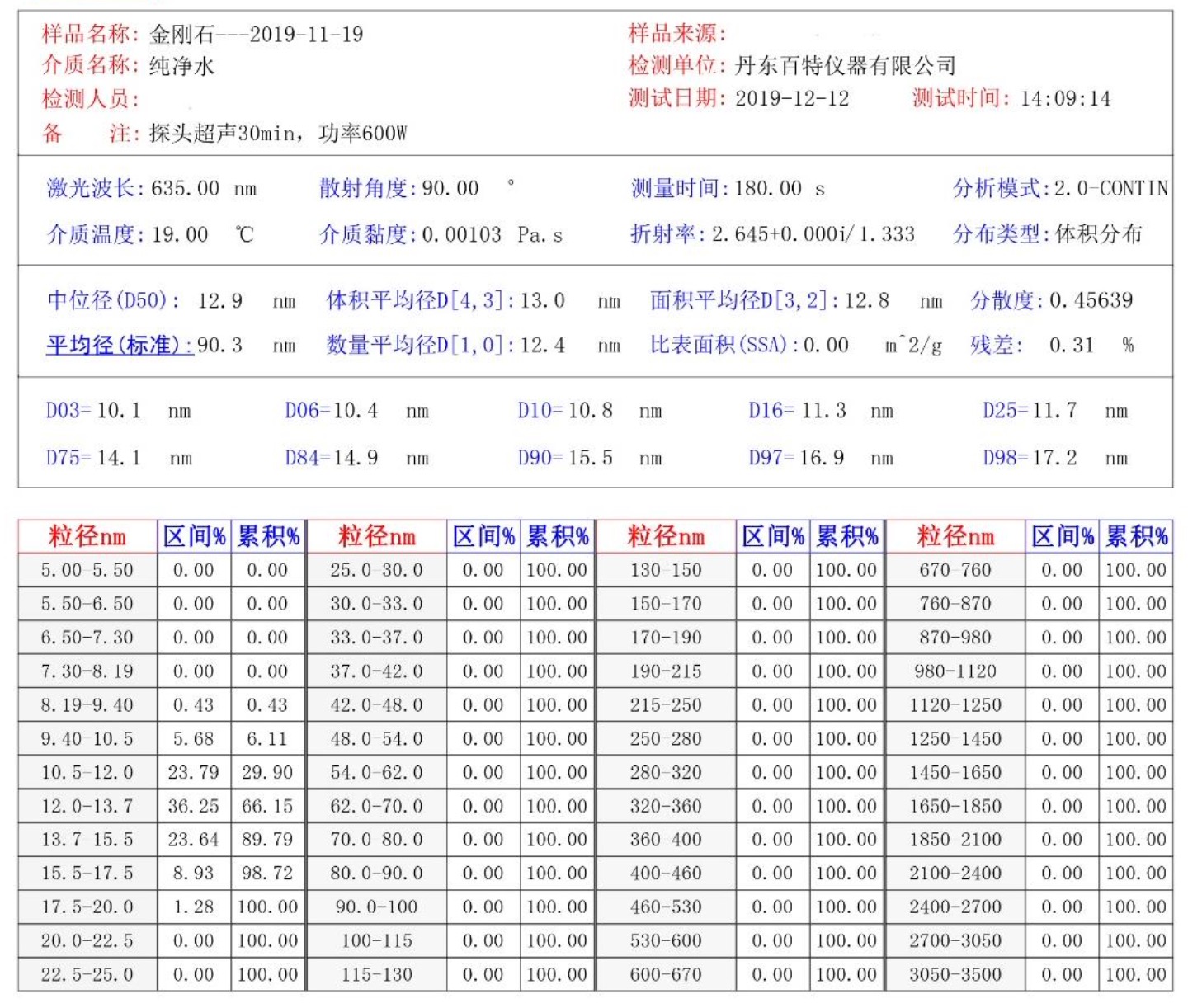

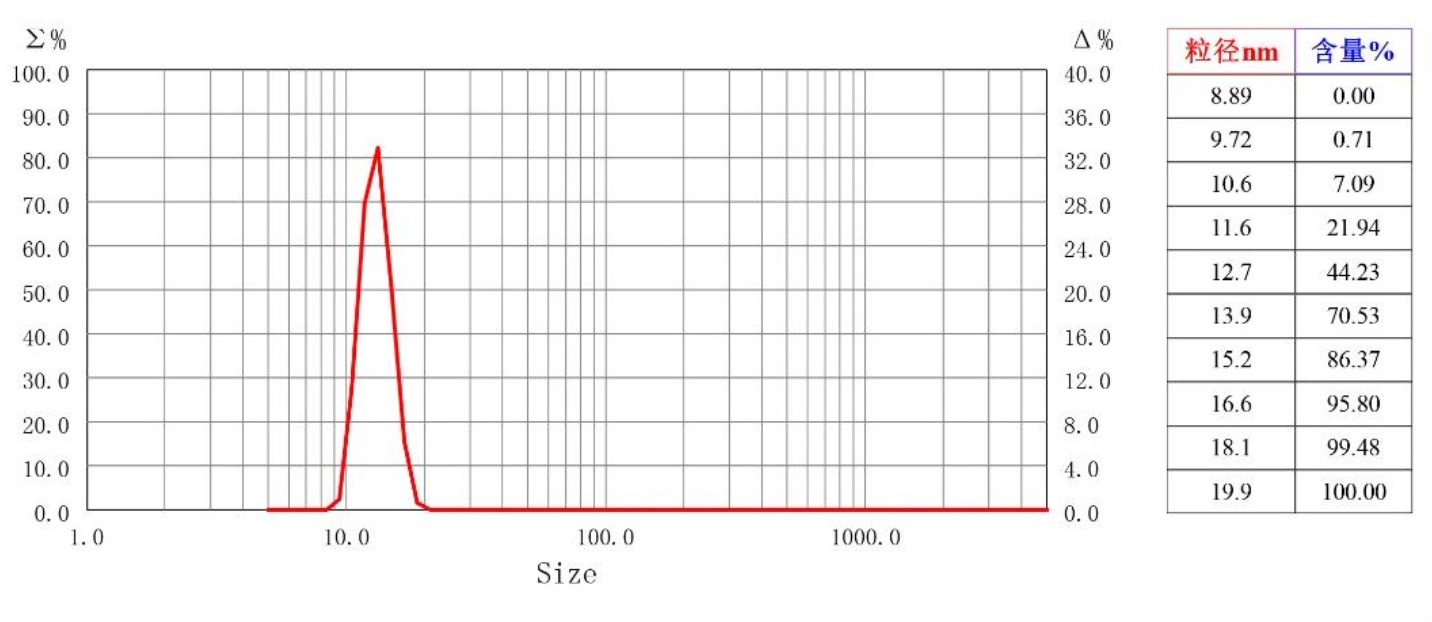

Diamond grinding pastes are made of high-grade large-grain diamond crystals as raw materials, and the most advanced powder preparation technology is used to sort out the diamond powder with extremely narrow particle size distribution (nano and micron). Strictly controlled nano and micro level single-crystal diamond crystal shape control system, so that the approximate circle value of each particle is almost perfect, successfully participates in the grinding and polishing process and obtains higher quality reproducibility. The diamond with a self-lubricating function is evenly distributed in the paste carrier. It can quickly polish metallographic sample materials with irregular surfaces (grooves, etc.), which is easy to use.

The characteristic of diamond abrasive paste is that the abrasive continuously rolls during the grinding process, producing two functions of extrusion and cutting, so that the convex and concave surface gradually becomes smooth and smooth.

Types of Diamond Paste

(1)Classification by solvent

The oil-soluble diamond paste has good wettability, low grinding force and grinding heat. It is mainly used for load mechanical grinding and processing high-quality carbide, high-carbon steel and other high-hard alloy parts, such as instruments, measuring tools, Cutting tools, abrasive tools, etc.

The Water-soluble diamond paste has low viscosity, easy removal, and high processing efficiency. It is mainly used for fine grinding of metallographic and petrographic samples, such as circuit boards, glass, ceramics, gems, agate and other non-metallic hard and brittle materials.

(2)Classification by diamond micropowder

According to the difference of the diamond powder used, it can be divided into polycrystalline diamond paste and single crystal diamond paste. Different from single-crystal diamond abrasive paste, polycrystalline diamond abrasive compound uses polycrystalline diamond powder as the main abrasive, which has strong self-sharpening properties and can meet the high standards of customers. It can also be seen from the color that the polycrystalline diamond paste is black.

Selection of diamond paste

The selection of diamond paste is mainly based on the finish requirements and processing efficiency of the workpiece, as well as the original finish of the workpiece. If the margin is large and the processing efficiency is high, the coarser grain size can be selected. if the margin is small and smoothness is required, the finer grain size can be selected. Therefore, rough grinding and fine grinding are generally selected according to the requirements of the workpiece finish. Refer to the following table:

The selection of diamond paste is mainly based on the finish requirements and processing efficiency of the workpiece, as well as the original finish of the workpiece. If the margin is large and the processing efficiency is high, the coarser grain size can be selected. if the margin is small and smoothness is required, the finer grain size can be selected. Therefore, rough grinding and fine grinding are generally selected according to the requirements of the workpiece finish. Refer to the following table:

(1)Selection of monocrystalline diamond grinding paste

|

Mesh |

Size(μm) |

Polishing Effect |

| 200000 Grit | 0-0.1 microns | The Finest Polishing |

| 100000 Grit | 0-0.25 microns | Final Polishing |

| 50000 Grit | 0-0.5 microns | |

| 14000 Grit | 0-1 microns | |

| 8000 Grit | 0-2 microns |

Mirror Finishing |

| 5000 Grit | 1.5-3 microns | |

| 4000 Grit | 2-4 microns | |

| 3000 Grit | 4-8 microns | Fine Polishing |

| 2000 Grit | 5-10 microns | |

| 1500 Grit | 7-14 microns | Pre-Polishing, Fine Lapping |

| 1200 Grit | 10-20 microns | Lapping Metals |

| 1000 Grit | 12-22 microns | |

| 800 Grit | 15-25 microns | Stock Removal or Lapping Metals |

| 600 Grit | 22-36 microns | |

| 500 Grit | 20-40 microns | Medium Fast Lapping |

| 450 Grit | 30-40 microns | |

| 400 Grit | 35-45 microns |

(2)Selection of polycrystalline diamond grinding paste

|

Mesh |

Size(μm) |

Polishing Effect |

| 60000 Grit | 0.5 | Super Mirror Polishing |

| 28000 Grit | 1.0 | |

| 8000 Grit | 3.0 | High Precision Polishing |

| 3000 Grit | 6.0 | Precision Polishing |

| 1800 Grit | 9.0 |

Application of the Diamond paste

The synthetic diamond compound is a soft abrasive paste made of selected high-quality diamond micro-powder abrasives and paste-like binders, preservatives, flavors, etc. It is suitable for measuring tools, such as glass, ceramics, gemstones, hard alloys, and other high-hardness materials. Grinding and polishing of cutting tools, optical instruments, and other high-finish workpieces. It is also suitable for special-shaped workpieces made of the above-mentioned materials that are difficult to process with a grinding wheel tool.

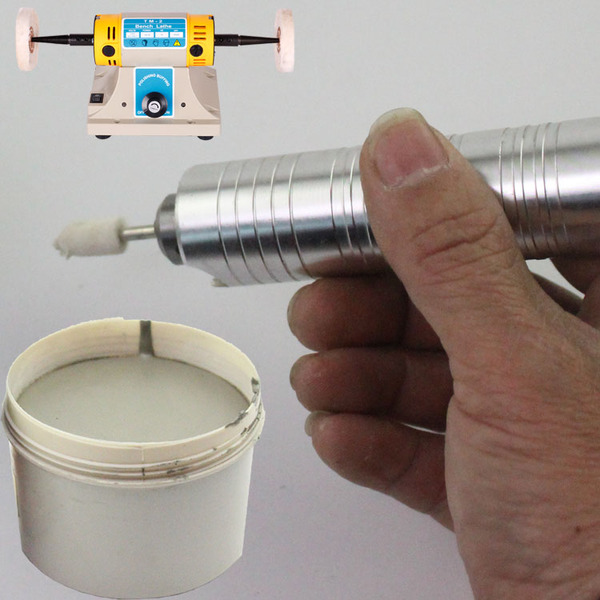

How to use diamond paste

Grinding paste is a type of surface finishing. Use the grinding effect of the abrasive paste to improve the surface roughness of the workpiece. How to use diamond paste?

According to the material and processing requirements of the workpiece, select the appropriate grinding device and grinding paste. Commonly used grinders are blocks and plates made of glass, cast iron, steel, aluminum, plexiglass and other materials, and kerosene is used as the diluent.

During manual polishing, the diamond paste should be applied to the polishing tool. During mechanical polishing, the abrasive paste should be applied to the workpiece. The pressure used during polishing, the hardness of the polishing tool and the grade of the abrasive paste should be adjusted and adapted to each other. When performing fine polishing, the pressure should be adjusted to be equivalent to the weight of the polishing tool.

- Diamond grinding is a kind of precision processing. During the processing, the environment and tools are required to be clean. The tools used must be dedicated for each particle size and must not be mixed.

- The workpiece must be carefully cleaned before changing to different grit abrasive compounds during processing, so as to prevent the coarse particles from the previous process from being mixed into the fine grit abrasive paste to scratch the workpiece.

- When polishing, squeeze a small amount of grinding paste into the container or directly squeeze it on the grinding device, and dilute it with a mixture of glycerin and distilled water at a ratio of 1:1. It can also be adjusted according to on-site use.

- After polishing, the workpiece should be cleaned with gasoline or kerosene.

Storage of Diamond Paste

- Do not squeeze during transportation and storage.

- The storage room temperature should be below 20oC.

- Store in a hygienic, cool and dry place.

Crownkyn superhard grinding and polishing material series are all preferred diamond abrasives. The advanced preparation process ensures that the high-quality particles are in an equal volume shape and the strict grading process ensures a high proportion of the final particle size and the uniformity of the particle size composition. The particle size range requirement is higher than the national standard.

Crownkyn Superhard diamond abrasive compound has a complete range of particle sizes and varieties, which can meet various requirements of users.